Take these things into consideration when purchasing industrial shredders or granulators

With the level of competition in the world of industrial equipment manufacturers and suppliers, it can be very challenging to make the right purchasing decisions.

This is no different when it comes to choosing the right shredder for your business. This goes for granulators as well.

Always consider the following before making the ultimate decision as to which industrial shredder to purchase.

The Material Being Shredded

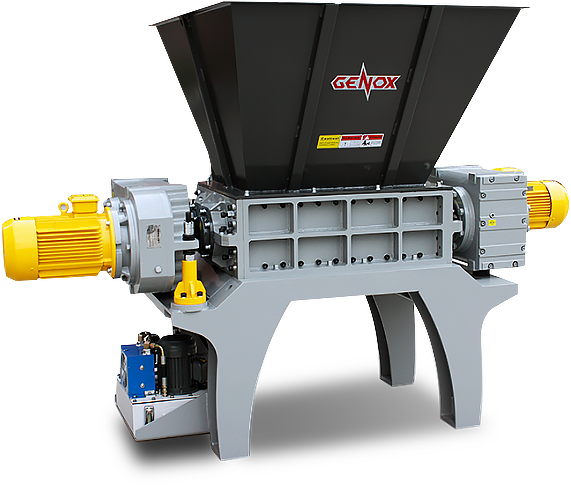

This is perhaps the first and most important thing to take into consideration. You need to take the type of material into account. You will find that there exist plastic shredders, wood shredders, paper shredders, rubber shredders, and any other material you can think of. You still, however, have to narrow It down as to the size, shape, and even weight of the items that you will be feeding into your shredder.

This will tell you how large a machine you need, its power, and the type of cutters that you need.

Your Required Results

What do you expect at the end of the day from your shredder? What volume of shredded material do you expect to have? What size particles should your finished product be shredded to?

Your expected output will help you further narrow down the specifics of your required machine.

Operating Conditions

At this point, you will have to take into consideration just how your shredding process will take place. You need to decide on how your shredder hopper will be loaded. Will it be hand-loaded, conveyor-loaded, or forklift-loaded? Also, what volume of product will you be feeding into the machine, and at what rate?

Your output conditions are also just as important. You have to ensure that your output process can keep up with the rate of input. The two have to be at a balance so that there is no loss of efficiency on either side.

For the output of the machine, you have to consider whether the machine’s discharge will gravity feed into a bin, be taken away with a screw auger, or on a conveyor belt. The gravity-fed bin is a bin placed under your shredder in which the shredded particles fall. The screw auger is a rotating screw that carries the shredded particles to the desired location. This can be opened or enclosed and is mainly used for semisolid material. A conveyor belt also carries the particles to the desired location. Conveyors are ideal if the material needs to be moved to distant or elevated locations.

Space and Power

The space available for the installation and usage of the shredder is very important. This is not only an operational issue but even more important, it is a safety issue. You have to have enough machinery clearance so that non-operators if the machine can move freely without having to interact with said machine. You also need enough room for operators to feel safe when loading the equipment.

The power available for using the shredder has to be ensured. You will need professional help to assess the power you have available for any additional equipment before purchasing and installing your shredder or granulator. The efficiency and lifespan of your shredder can be greatly reduced if it is operating with a substandard power source.

If you need more assistance in selecting the best shredder to suit your requirements, get in touch with Applied Machinery Australia. As one of Australia’s largest and most respected dealers of premium quality shredders, they have got all your machinery needs covered.